- HOME

- INDUSTRIES

- DIGITAL MANUFACTURING

- ANSYS

- STRUCTURES

Ansys Structures

Structural Analysis and Simulation Software Solutions

Contact us

Ansys Structure - Static Structural Analysis

Ansys provides structural analysis software that allows engineers to tackle complex structural engineering issues more quickly and effectively. Engineers can use these tools to perform finite element analyses (FEA), customise and automate structural mechanics solutions, and can evaluate different design scenarios. Businesses can save production costs by reducing the number of design cycles and can get products to market faster by using this software early.

Engineers can simulate shock, drop, and vibration, impact and penetration, smashes and crashes, occupant safety, heat transfer, solder fatigue, repetitive loads, and much more with our comprehensive array of structural analysis tools. Ansys structural analysis helps you address your hardest product challenges with a variety of applications and product integrations.

Ansys Structure Products

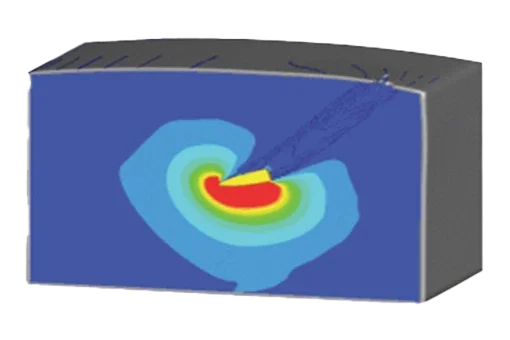

Ansys Autodyn

Ansys Autodyn is a highly advanced simulation software specifically designed for analyzing and simulating material deformation and failure. It excels in capturing complex physical phenomena, including the interaction of solids, liquids, and gases, material phase transitions, and shock wave propagation. With Autodyn, engineers and researchers can gain a deep understanding of structural behavior under high-energy events and explosive scenarios. Autodyn's capabilities empower users to optimize designs, enhance safety, and mitigate risks associated with structural failure.

Features :

- Strain Life (EN)

- Stress Life (EN)

- Dang Van

- Safety Factor

- Seam Weld

- Spot Weld

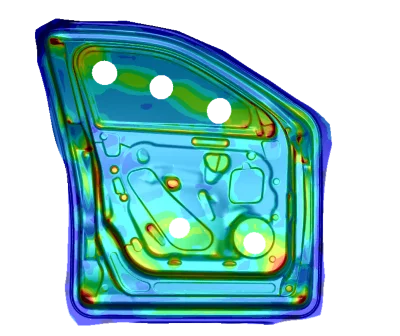

Ansys Forming

Ansys Forming is a specialized software solution for simulating and analyzing metal forming processes, such as sheet metal stamping, forging, and extrusion. It provides advanced simulation capabilities to predict material flow, formability, springback, and other crucial parameters. With Ansys Forming, engineers can optimize tool designs, reduce material waste, and improve manufacturing efficiency. The software offers a comprehensive range of features, including meshing, material modeling, contact analysis, and post-processing tools, empowering users to achieve accurate and reliable simulations for the metal forming industry.

Features :

- Process Definition

- CAD Model Import

- Auto Tooling Meshing

- Blank Auto-Meshing

- Job and Tool Setup

- Drawbead Definition

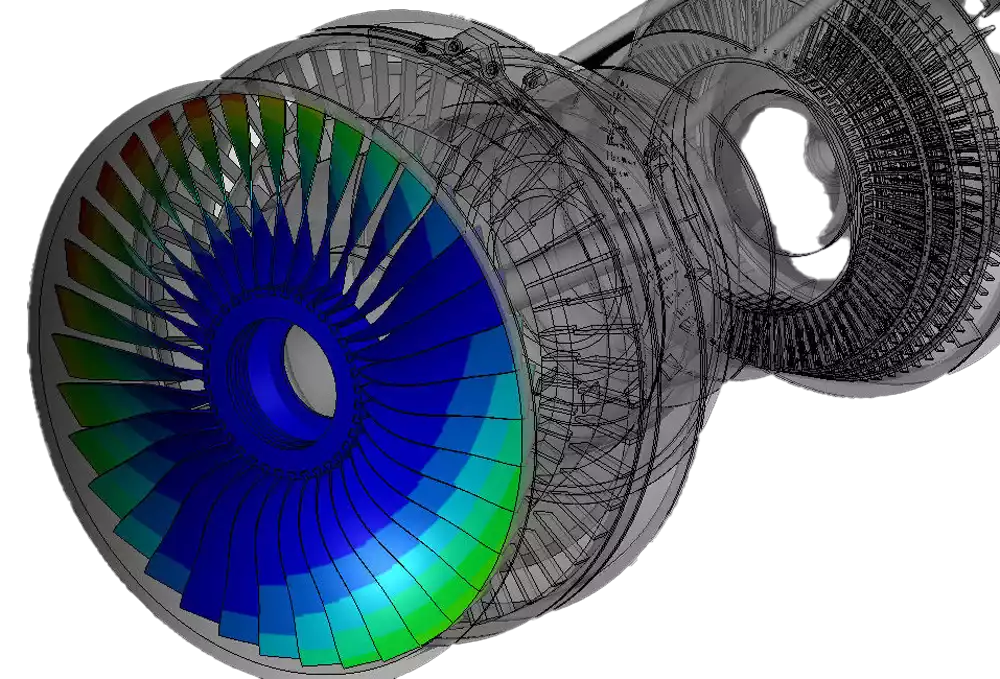

Ansys LS-DYNA

Ansys LS-DYNA is a leading explicit simulation program widely recognized for its capability to accurately simulate material behavior under sudden and intense loading conditions. With its extensive selection of elements, contact formulations, material models, and control options, LS-DYNA offers a versatile platform for simulating complex models while maintaining control over every detail of the problem. It enables engineers to accurately predict and analyze the response of materials to dynamic events and impact scenarios, making it a valuable tool in industries such as automotive, aerospace, defense, and manufacturing.

Features :

- Implicit and Explicit Solvers

- Frequency Domain Analysis

- ICFD for Incompressible Fluid

- Electromagnetics Solver

- Multiphysics Solver

- Particle Methods

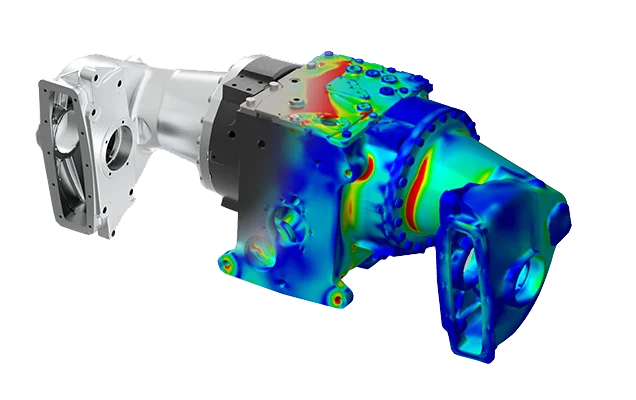

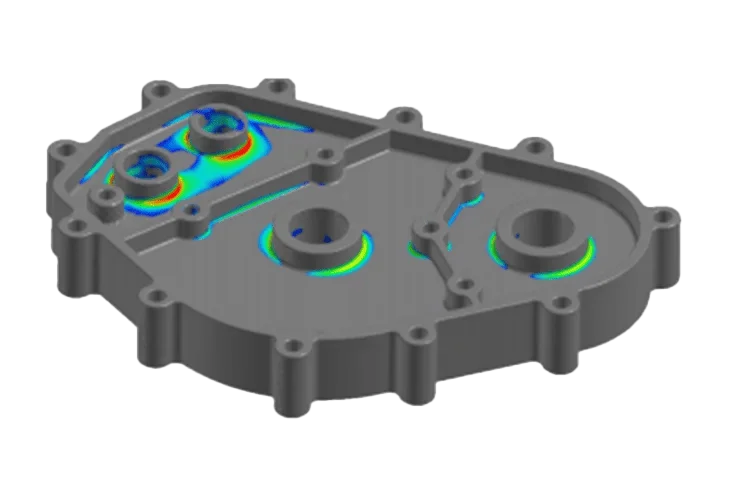

Ansys Mechanical

Ansys Mechanical is a powerful finite element analysis (FEA) software widely used for simulating and analyzing the structural behavior of various components and systems. It offers comprehensive capabilities for linear and nonlinear static analysis, dynamic analysis, modal analysis, and buckling analysis. The software supports a wide range of material models, allowing for accurate representation of material behavior. With integrated multiphysics capabilities, engineers can couple structural analysis with other physical phenomena to simulate complex systems.

Features :

- Linear Dynamics

- Nonlinearities

- Thermal Analysis

- Fluid-Structure Interaction

- Customization and Scripting

- Solve Management

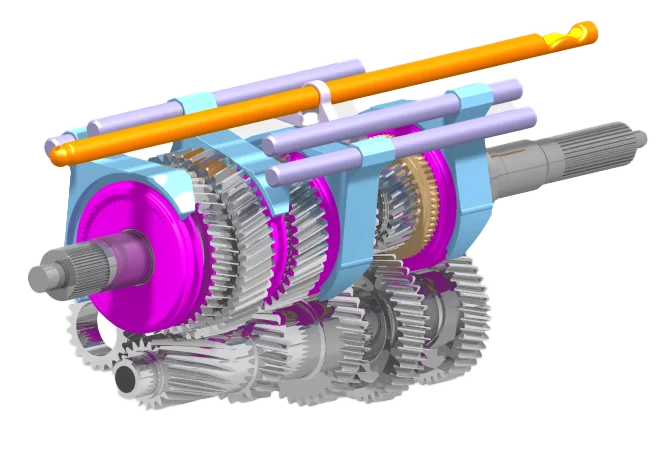

Ansys Motion

Ansys Motion is a multi-body dynamics simulation software that enables engineers to analyze the kinematic and dynamic behavior of mechanical systems. It provides accurate simulations of rigid and flexible bodies, joints, actuators, and constraints. With built-in motion analysis capabilities, engineers can evaluate system performance, predict forces, torques, and motion trajectories. Ansys Motion is widely used in industries such as automotive, robotics, aerospace, and machinery to optimize designs and improve product performance.

Features :

- Multi-body dynamics

- Kinematic analysis

- Rigid and flexible bodies

- Joints and constraints

- Motion trajectory prediction

- Force and torque evaluation

Ansys Ncode

Ansys Ncode DesignLife works with Ansys Mechanical to conduct a dependable assessment of fatigue life. By utilizing the finite element analysis (FEA) results from Ansys Mechanical and Ansys LS-DYNA, it collates damage arising from repetitive loading to determine the anticipated lifespan of a product. With this tool, you can rapidly evaluate how diverse materials and alternative geometries would impact new designs, optimize them for the product's anticipated usage, and achieve this before constructing the initial prototype or incurring costly testing expenses.

Features :

- Strain Life (EN)

- Stress Life (EN)

- Safety Factor

- Vibration Fatigue

- Thermo-Mechanical Fatigue

- Adhesives Bonds

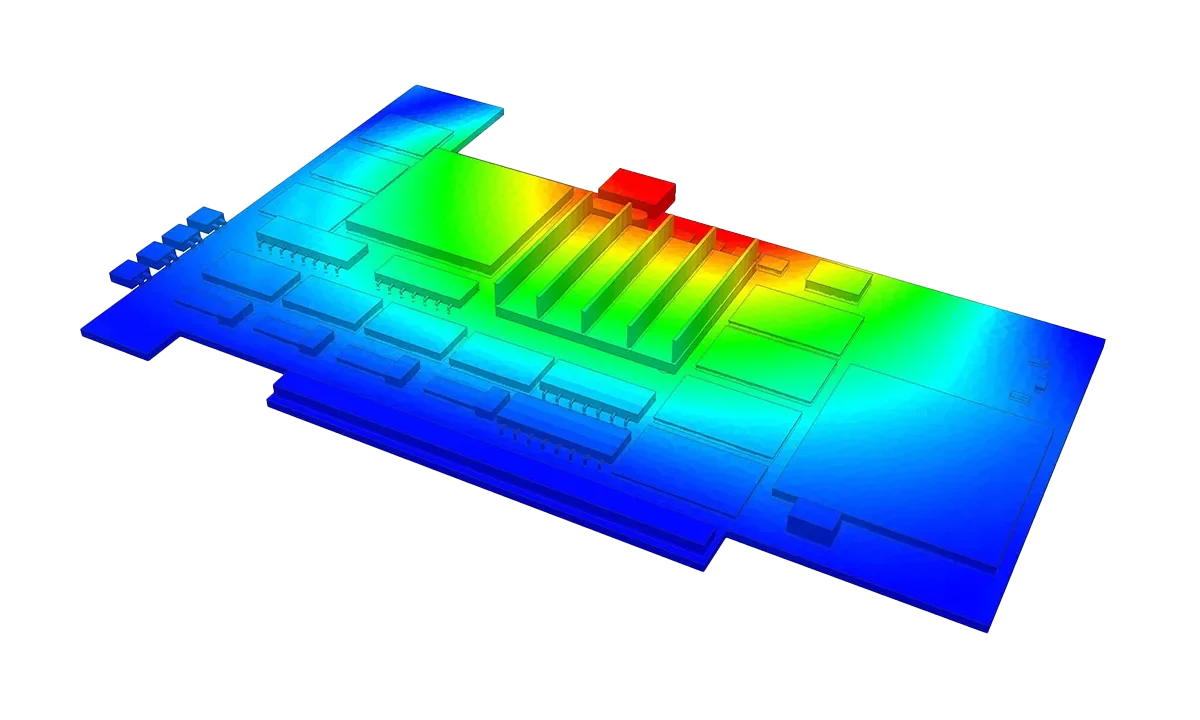

Ansys Sherlock

Ansys Sherlock expedites precise life predictions for electronic hardware at the component, board, and system levels in the early stages of design. By allowing designers to accurately model silicon-metal layers, semiconductor packaging, printed circuit boards (PCBs), and assemblies to anticipate failure risks due to thermal, mechanical, and manufacturing stressors, Sherlock circumvents the traditional 'test-fail-fix-repeat' cycle. This tool empowers you to predict potential failure modes well in advance of the prototype phase.

Features :

- Electronics reliability analysis

- Failure prediction

- Component-level assessment

- Stress and thermal analysis

- Design optimization

- Risk assessment

GOT ANY QUERIES?

We are here to answer