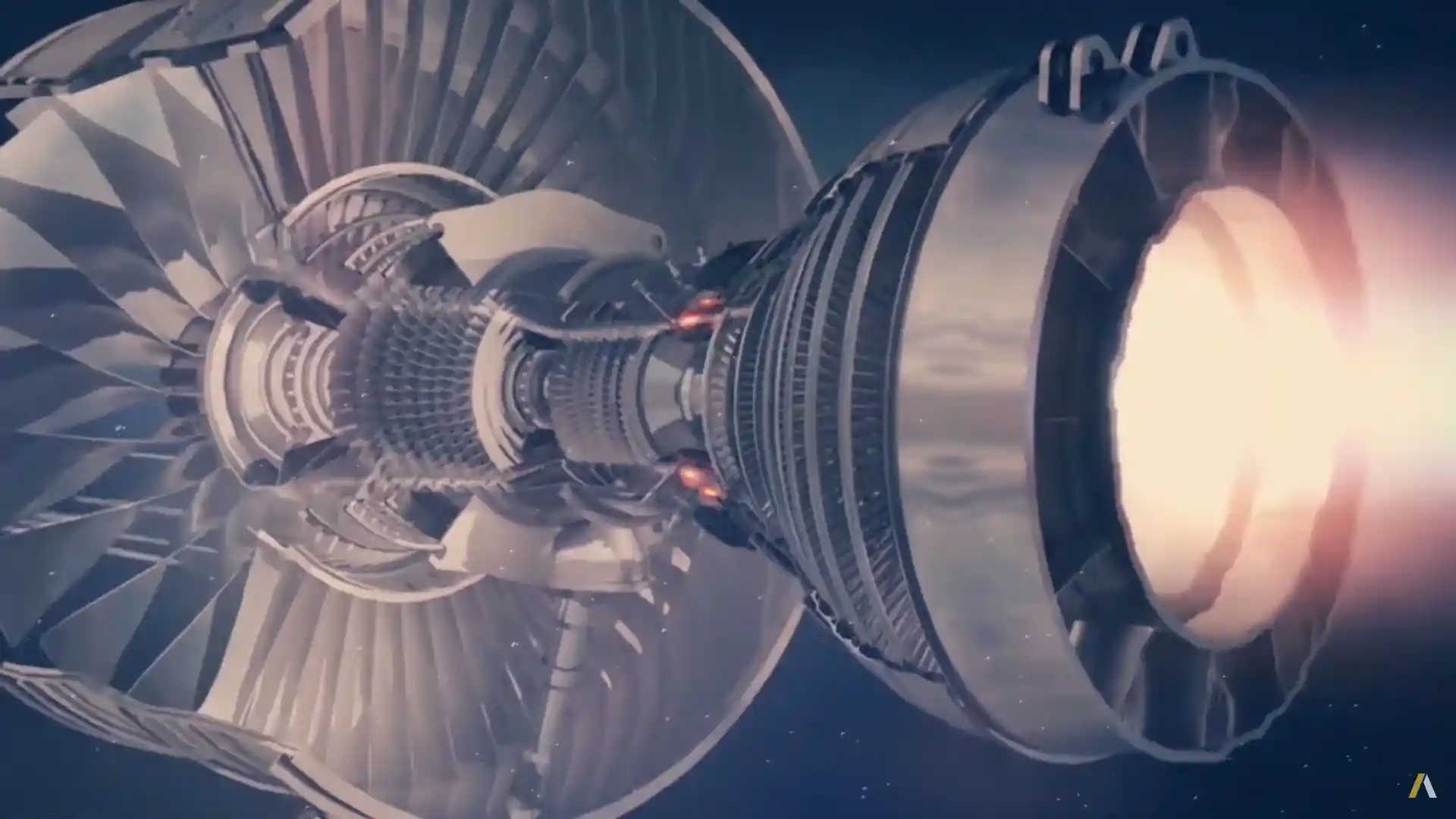

Founded in 1970, Ansys software has enabled innovators across industries to push boundaries with the predictive power of simulation. From sustainable transportation and advanced semiconductors to satellite systems and life-saving medical devices, the next great leaps in human advancement will be powered by Ansys.

Ansys Simulation Software Distributor in India

ANSYS is the best simulation software which enables organizations to confidently predict how their products will operate in the real world. We believe that every product is a promise of something greater.

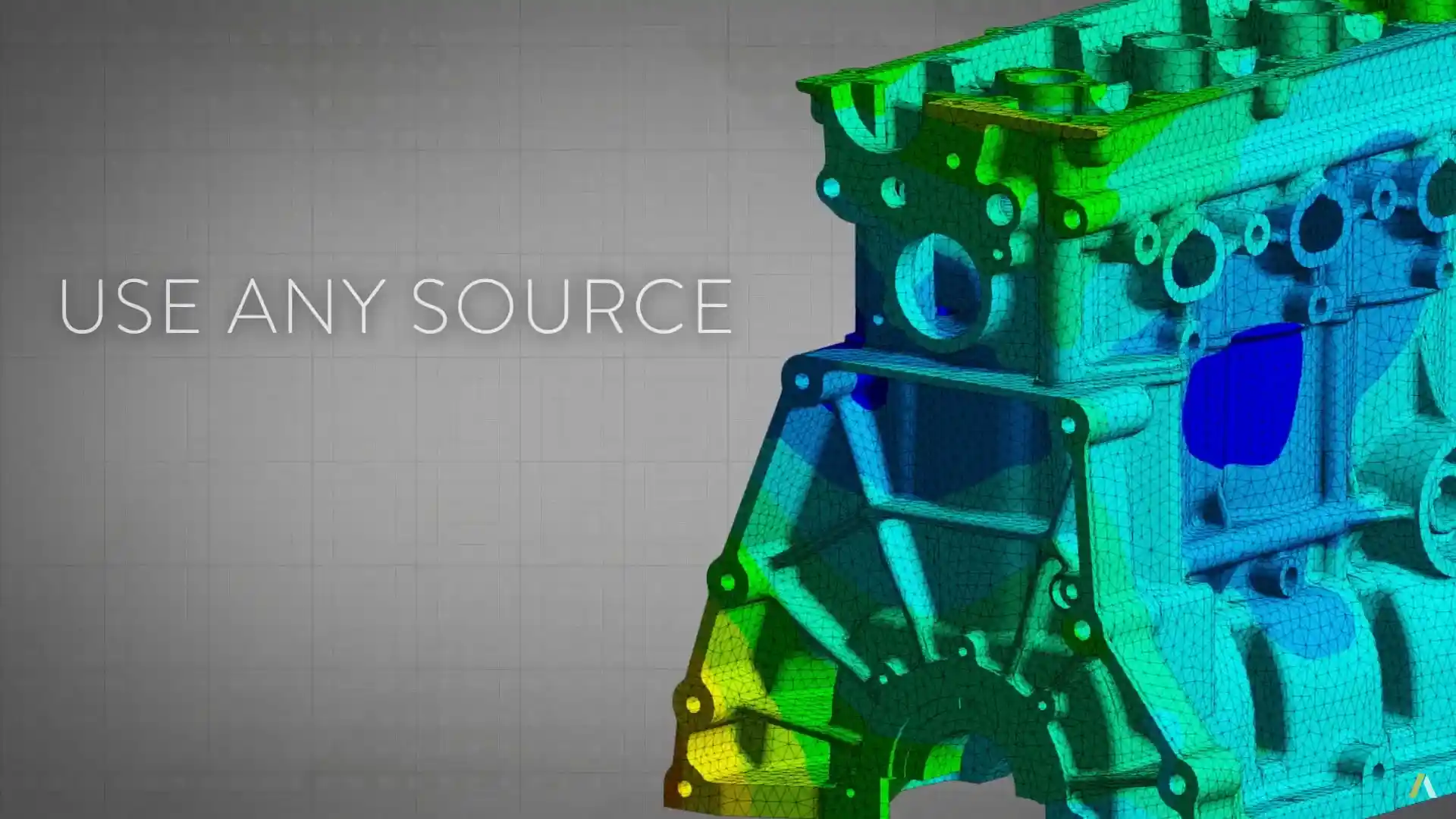

Simulation-Driven Product Development takes engineering simulation to another level-the unequalled depth and breadth of our best 3d software coupled with its unmatched engineered scalability, comprehensive multiphysics foundation and adaptive architecture set our technology apart from other CAE tools. These ANSYS advantages add value to the engineering design process by delivering efficiency, driving innovation and reducing physical constraints, enabling simulated tests that might not be possible otherwise.

Ansys Products

Instantaneous simulation results as models are designed and edited

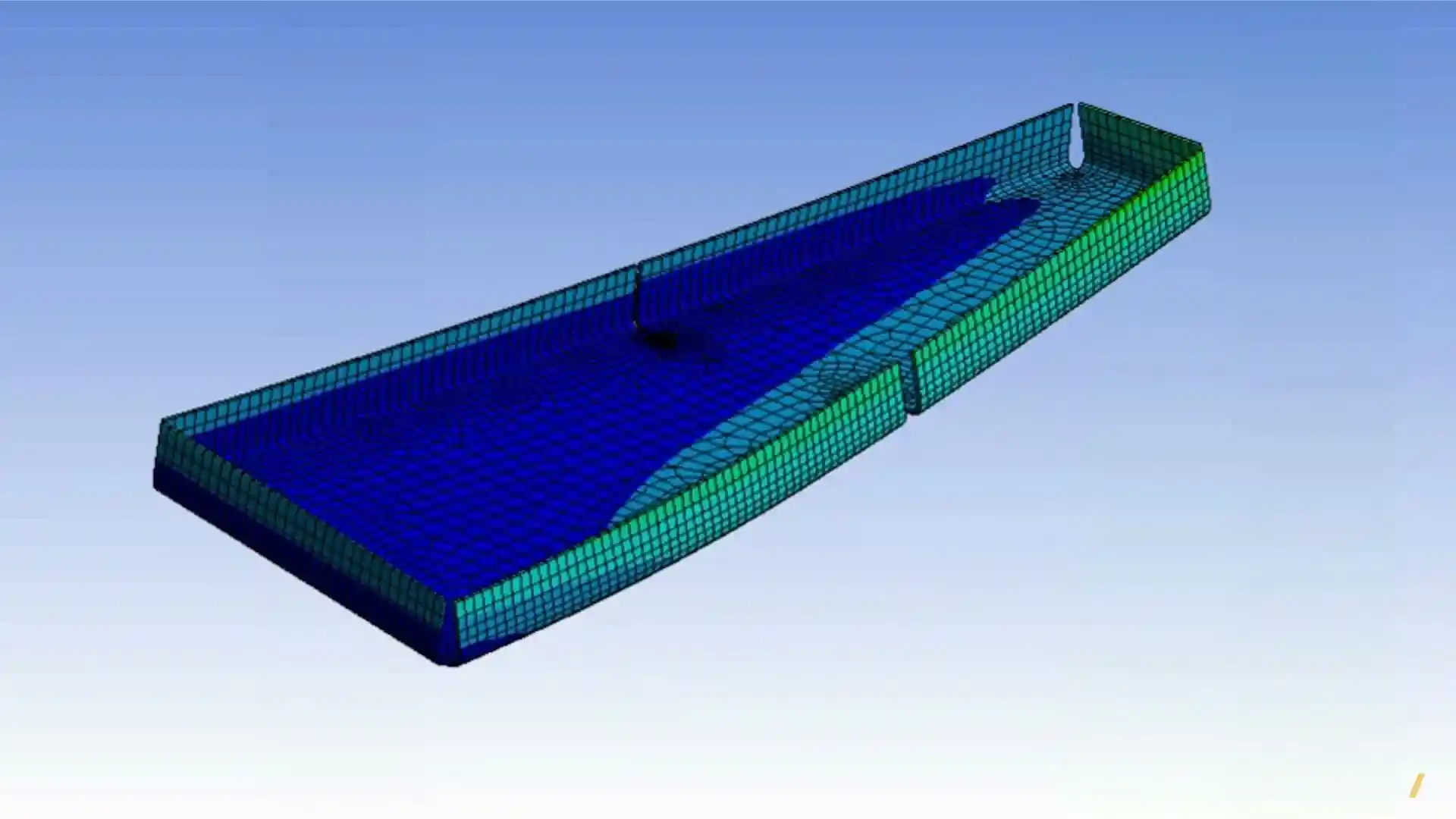

Ansys Simulation software enables product development engineers to gain insights that were previously possible only through making and breaking expensive prototypes. However, such software isn’t for every engineer. With its Discovery Live technology, ANSYS revolutionizes product design. This 3D simulation software provides instantaneous simulation results while you design and edit and enables you to experiment with design ideas for on-the-spot feedback. These immediate insights make simulation useful and relevant to every engineer for upfront CAE. Discovery Live’s speed and simplicity represent a quantum leap forward in simulation technology, and it enables you to spend more time with answers instead of questions.

With Discovery Live, you can:

- Experiment with design ideas, easily make changes and receive instantaneous engineering insights

- Perform 10 to 1,000 simulations in the same timeframe that was once needed to perform just one simple simulation

- Simulate on newly created models or any imported CAD file

- Investigate more options earlier in the design process and develop new products that get to market faster

- Explore all your “what if” design ideas at little to no cost in time and effort

- Facilitate breakthroughs and innovations and take your engineering efforts to the next level

Case Studies

From new software implementation to discovering emerging technologies, find the resources you need to make more things possible.

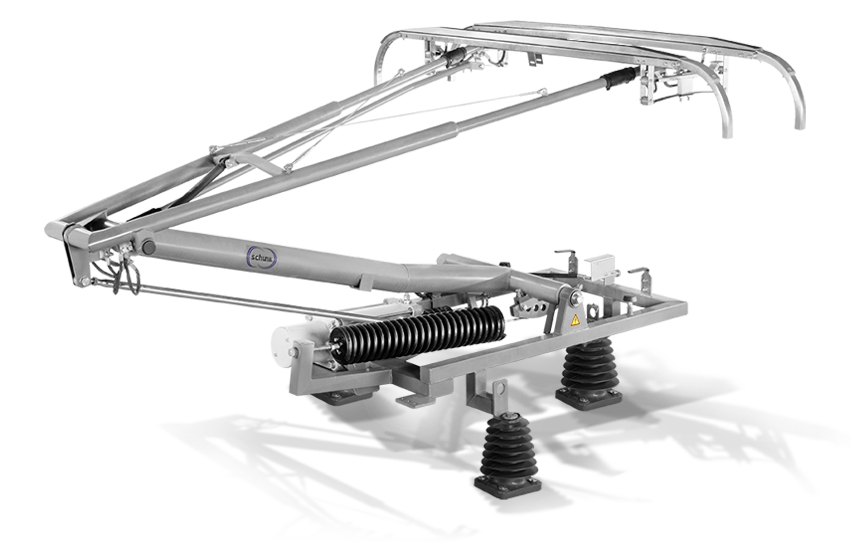

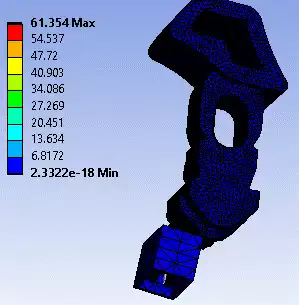

Resolving Orthogonality, Mesh & Convergence Issues in Pantograph : Success Story.

Through Aerodynamic Analysis Using Ansys Fluent Onward Technologies Solved Pantograph Orthogonality and Convergence Issue.

Case Study

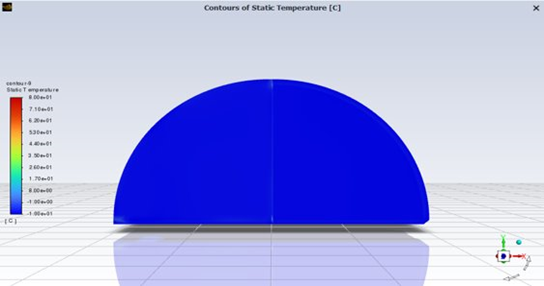

Capturing 24-Hour Cycle of Shelter Behaviour with Transient 3D Simulation : Success Story.

Deepali Designs & Exhibits can now rely on Ansys simulation tools, with the support of ARK Infosolutions, to simulate complex environmental conditions.

Case Study

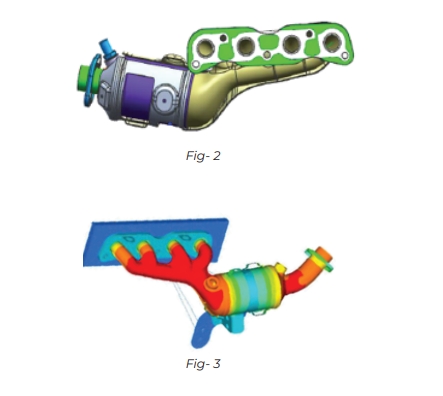

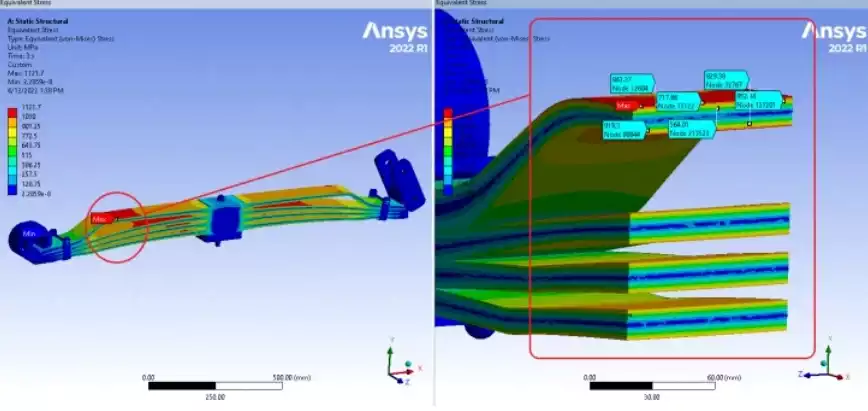

FEA Simulation and Design Optimization using Ansys Workbench : Success Story.

Through ANSYS Workbench, They were able to anticipate the temperature distribution and fatigue characteristics of the product.

Case Study

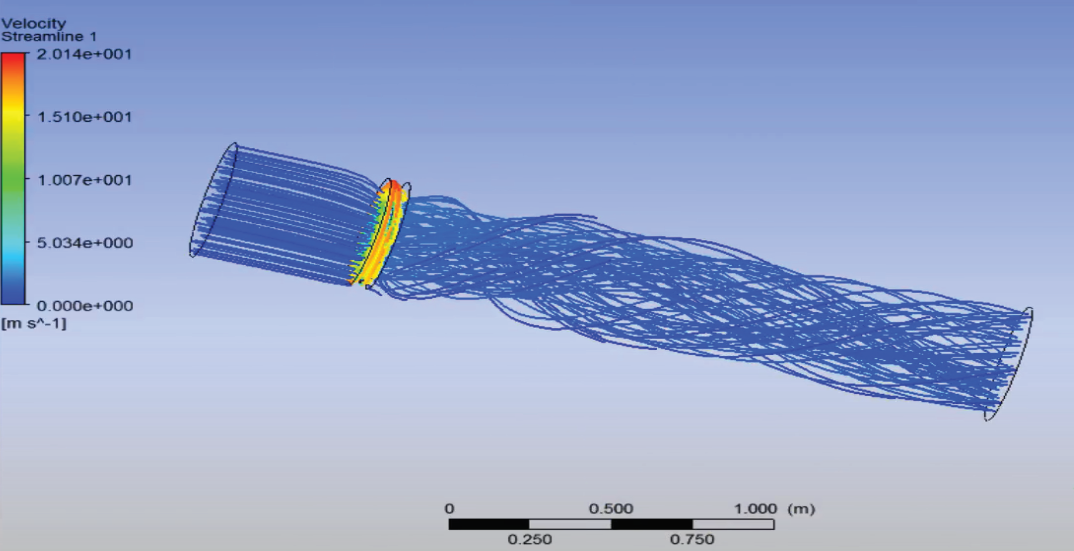

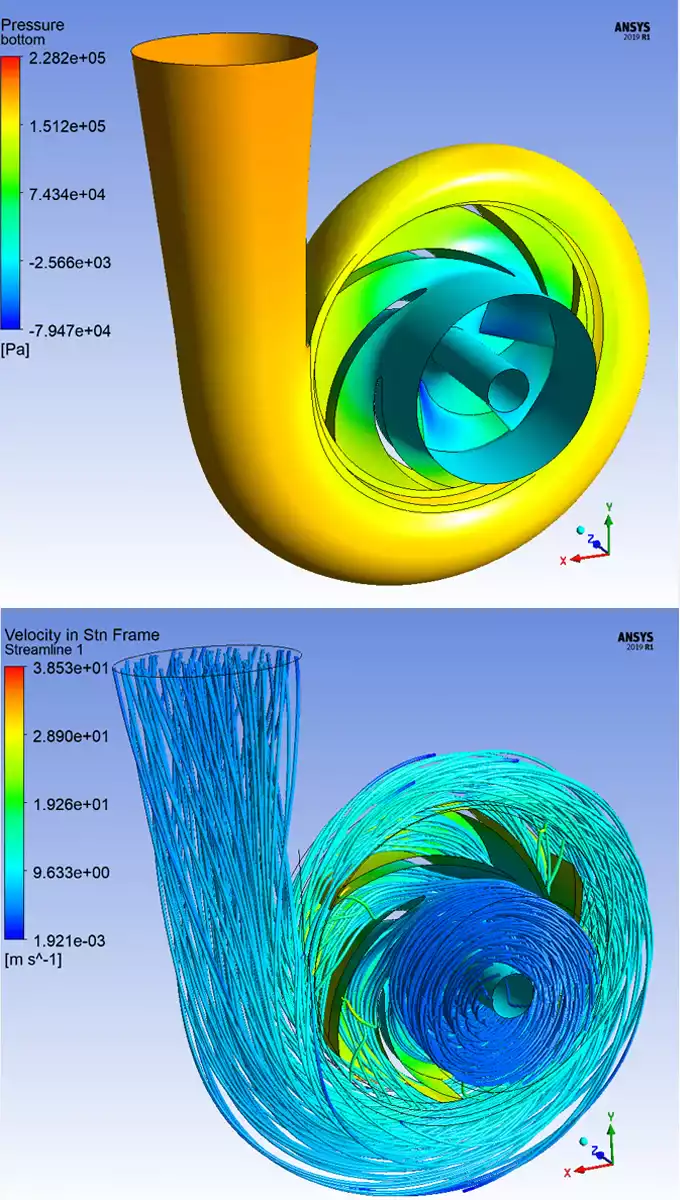

Fan Modeling using Ansys Fluent : Success Story.

Through ANSYS simulation, the system flow rate is determined by balancing system losses with the fan curve. Accurate results were achieved through a detailed fan modeling approach that considers factors such as RPM and flow rate and ensures that system reliability and efficiency are optimized.

Case Study

Revolutionizing Spacecraft Safety with Advanced Eddy Current Brake Design Using Ansys Maxwell

Through Ansys Maxwell, we can ensure the performance and safety of aircraft with the Eddy Current Braking System.

Case Study

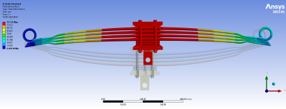

Optimizing Leaf Spring Design for Varied Applications: Through Ansys Mechanical : Success Story

Ansys provides unparalleled capabilities in accurately simulating the behavior of leaf springs, allowing for robust design optimization, enhanced product quality, and streamlined development processes.

Case Study

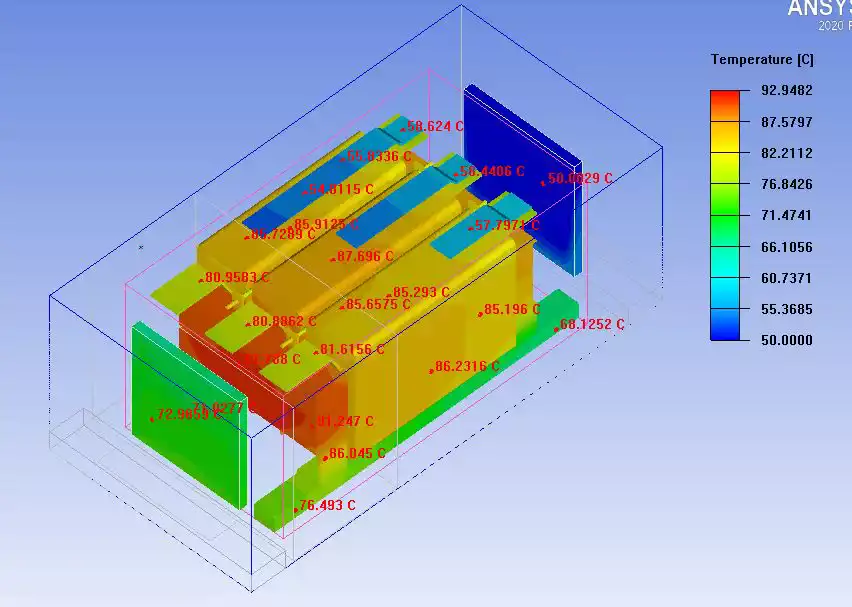

Optimising Product Reliability: Through ANSYS ICEPAK Simulation : Success Story.

Through Ansys Icepack, they were able to achieve perfect Inductor Orientation and proper Air Flow in an EV Charger.

Case Study

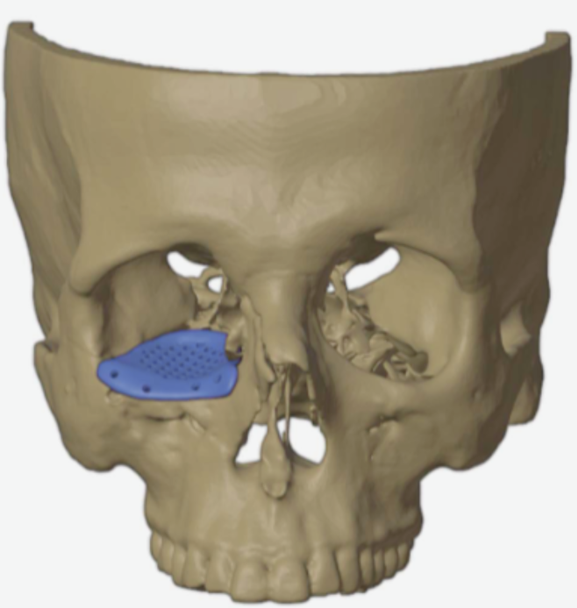

Optimizing design for Medical Implants & solving complex biomechanics of bones: Through Ansys FEA : Success Story.

ANSYS enables accurate simulation, streamlined development, and personalized optimization of medical implants and enhancing patient specific outcomes.

Case Study

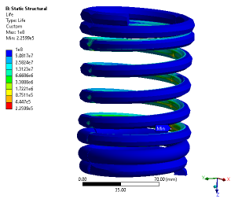

Solving stress levels and fatigue life of helical springs: Through Ansys Mechanical

Implementing Ansys Mechanical at Coventry Coil-o-Matic has brought numerous benefits, including predicting stress levels and fatigue life for helix springs under different loads and operating conditions within the Ansys Mechanical system.

Case Study

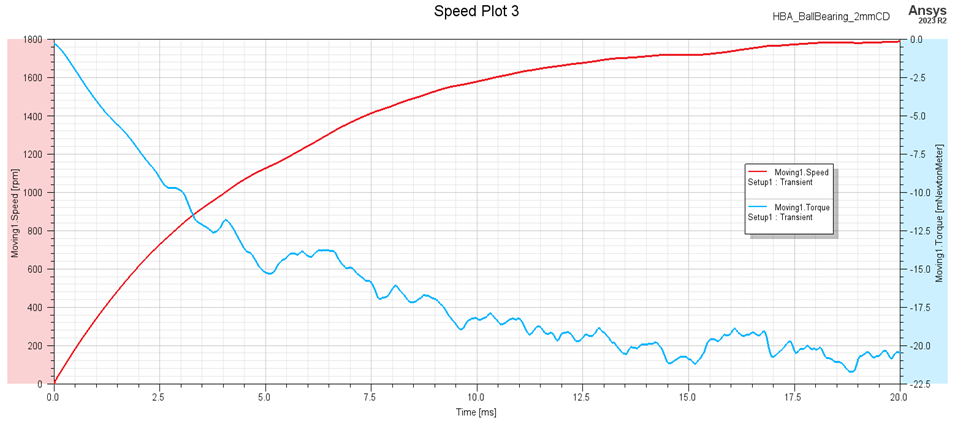

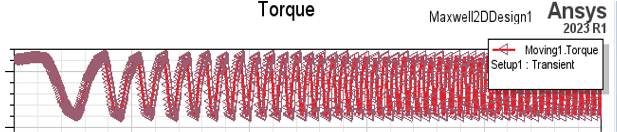

Maintaining Consistent Torque During Rapid Acceleration: Through Parametric Analysis in Maxwell Design

Incorporating Maxwell Simulation into its operations, Matter Motor Works has realized a myriad of advantages. The application has enabled the careful equilibrium of consistent torque with considerations such as efficiency, weight, and manufacturing constraints.

Case Study

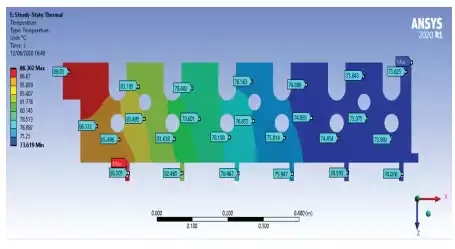

Enhancing Electrical Performance: Through Q3D Simulation and Redesign Efficiency : Success Story.

Transforming operations at Hi-Rel Electronics Pvt. Ltd., ARK Infosolutions utilized advanced engineering with Q3D 3D Extractor. Precise busbar loop inductance analysis and steady-state thermal mapping optimized performance and space utilization.

Case Study

Unveils EMI Filter Power Circuit Noise Attenuation Boost with ANSYS Simulation : Success Story

Sienna ECAD used ANSYS simulation for successful noise suppression in both modes, optimizing design, expediting evaluation, and reducing project timelines.

Case Study

Effortlessly Modeling Non-Linearities with Ansys Workbench: Success Story

FEA compared with Burst tests for ASME U stamp compliance, ensuring safety, design accuracy, and cost-effectiveness.

Case Study

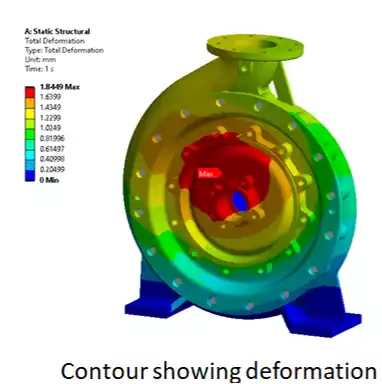

Predicting the pump profile with Ansys Mechanical: Success Story

Pumpsense Fluid Engineering achieved impressive results in simulating stress levels and total deformation in centrifugal pumps by considering contact nonlinearity and utilizing Ansys Mechanical.

Case Study

Unlocking Design Efficiency with Ansys Mechanical: Success Story

ARK Infosolutions technical team provided Napino Auto & Electronics Limited with an Ansys simulation solution that utilized spring probe plotting against deformation/displacement in Ansys Mechanical.

Case Study

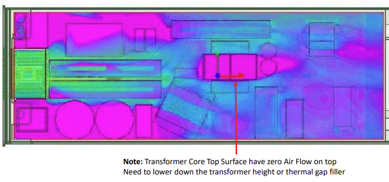

Predicting the Thermal Performance with Ansys ICEPAK: Success Story

ARK Infosolutions provided Ansys ICEPAK to Hitachi Hi-Rel Power Electronics Private Limited by simulating magnetics under full load conditions, incorporating fan and filter boundaries.

Case Study

Streamlining the Design Process with ANSYS Mechanical

Ansys Mechanical is a best-in-class finite element solver with structural, thermal, acoustics, transient andnonlinear capabilities to improve your modeling.

Case Study

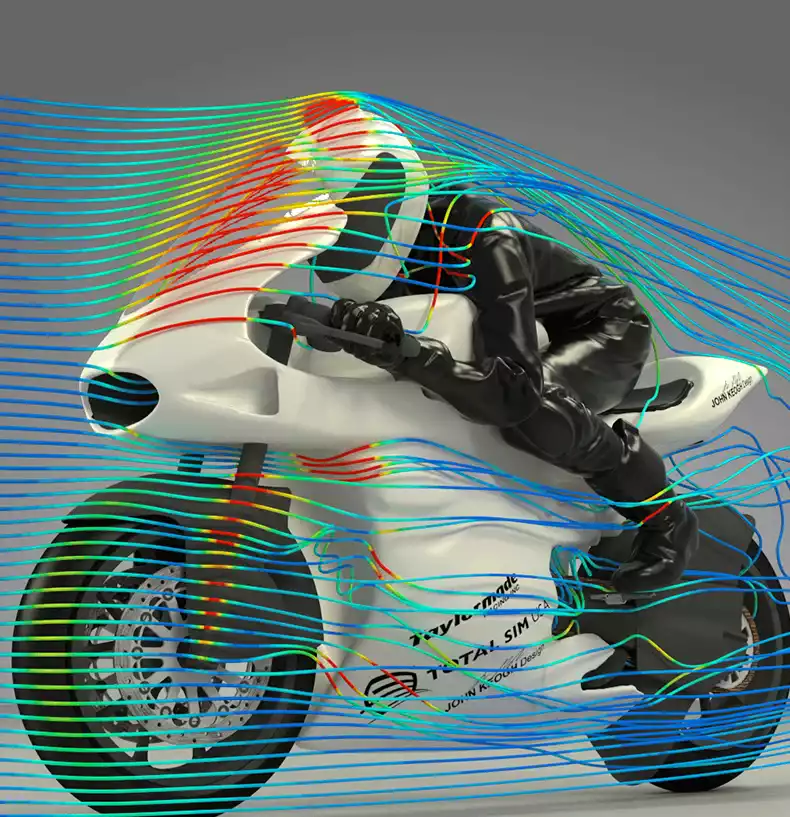

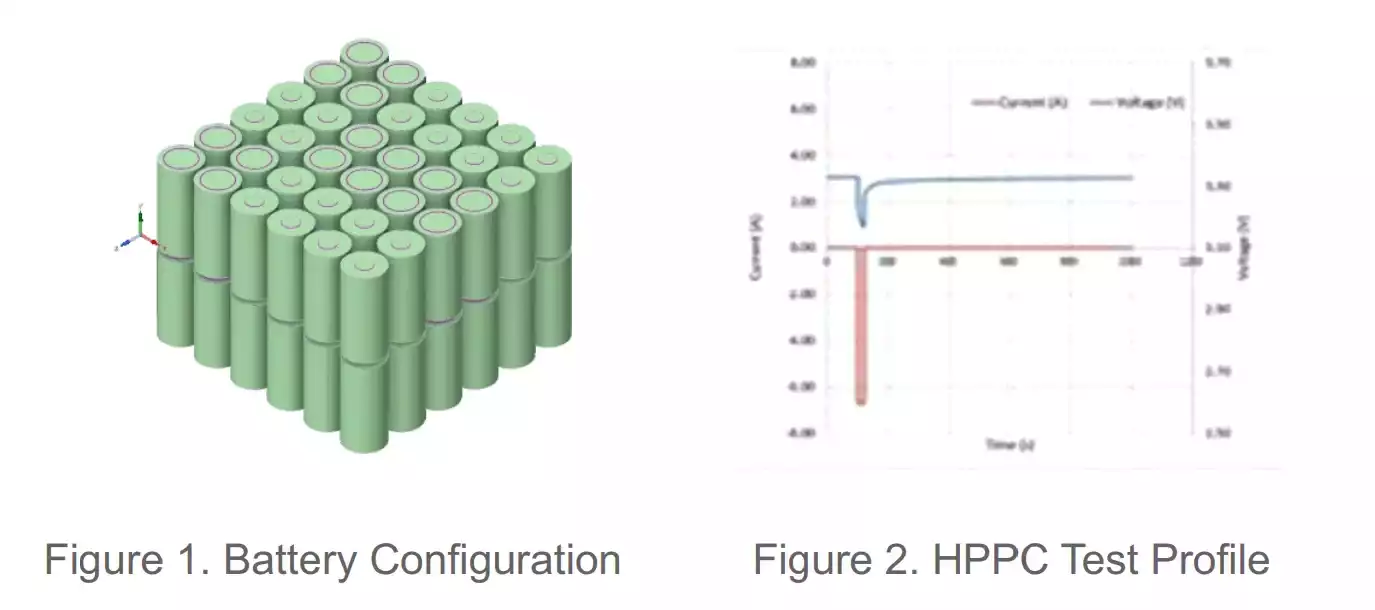

Reducing Drag and Improving Efficiency in Electric Vehicles with Ansys Fluent

Ansys Fluent is a powerful computational fluid dynamics (CFD) software that can be used to solve challenges inelectro-thermal coupled analysis of battery packs for estimating thermal behaviour.

Case Study

Academic License

Thousands of universities around the world use Ansys Academic engineering simulation software to help undergraduate students learn physics principles; researchers solve complex engineering problems; and postgraduate students produce data for their master’s theses or doctoral dissertations.

The Academic Program also offers unique materials education resources, which support teaching of engineering, science and design curriculum.

Engineering simulation is a key skill that many companies are seeking in the employees they hire. For students to graduate with this expertise, engineering simulation needs to be part of the curriculum. Simulation helps students at all levels, including those in STEM programs, undergraduate programs and postgraduate research positions.

ANSYS is committed to working with academia to provide a solution flexible enough to appeal to all users. The low-cost, high-performance bundles of ANSYS simulation technology include structural, thermal, fluid dynamics, electronics and multiphysics solvers, ANSYS Workbench, CAD import tools, solid modelling, advanced meshing and post-processing features.

Click below to start a conversation with the team.

FAQ's

A. Ansys is a leading provider of engineering simulation software. Their software solutions enable engineers and designers to simulate and analyze various physical phenomena, helping them optimize product designs, improve performance, and reduce time-to-market.

A. Digital manufacturing is the use of digital technologies, such as computer-aided design (CAD), computer-aided manufacturing (CAM), and simulation software, to model, simulate, and optimize manufacturing processes. It allows manufacturers to digitally prototype and optimize production systems, reducing costs and improving efficiency."

A. Ansys simulation software provides tools for simulating and analyzing various aspects of the manufacturing process. It can be used to optimize manufacturing processes, evaluate different production strategies, analyze material behavior, predict and reduce manufacturing defects, and optimize product quality.

A. Ansys offers a range of simulation capabilities for digital manufacturing, including:

Process simulation: Simulating manufacturing processes such as welding, casting, injection molding, additive manufacturing (3D printing), and more to optimize process parameters and minimize defects.

Material behavior analysis: Simulating material behavior under different manufacturing conditions to understand how it affects the final product's performance and durability.

Assembly simulation: Simulating the assembly process to evaluate fit and tolerance, identify potential interferences, and optimize assembly sequences.

Factory layout optimization: Simulating and optimizing factory layouts to improve material flow, minimize bottlenecks, and optimize production efficiency.

Production line simulation: Simulating production lines to optimize throughput, minimize cycle times, identify potential issues, and improve overall productivity.

Virtual commissioning: Simulating the behavior of automated systems and control software to validate their performance before implementation.

A. Yes, Ansys simulation software can integrate with other digital manufacturing tools such as CAD, CAM, and product lifecycle management (PLM) software. This integration allows for seamless data transfer and collaboration between different stages of the product development and manufacturing process.

A. Yes, Ansys simulation software caters to a wide range of manufacturing companies, from small enterprises to large corporations. Ansys offers different software packages and licensing options to suit the specific needs and budgets of different organizations.

A. Yes, Ansys provides comprehensive training programs and support resources to help users make the most of their simulation software. They offer online tutorials, documentation, webinars, and in-person training courses. Additionally, Ansys has a global support network to assist users with any technical issues or questions they may have.

A. ARK Infosolutions is the authorized value-added distributor, reseller, and service provider for Ansys in India, offering comprehensive support and competitive pricing for customers looking to effectively implement and utilize Ansys.

A. To get in touch with ARK Infosolutions Pvt. Ltd., kindly fill up an enquiry form on our website or contact our sales representative by sharing your details/requirements at ansys@arkinfo.in. We will be happy to assist you with product inquiries, licensing options, pricing, technical support, and training services.

Related Blogs

- The Future of Manufacturing: 3D Printing and Additive Manufacturing

- ARK Infosolutions Opens 3D Printing Experience Centre to Boost 3D Printing Services

- Transforming Additive Manufacturing with ARK Infosolutions: Bringing Next-Level Solutions to the Industry

- 4 Industries Leveraging 3D Printing Technology

- 3D Printing Trends! A Radical Year Ahead in 2021

GOT ANY QUERIES?

We are here to answer